In the quiet hum of a Swiss laboratory, a revolution in material science is unfolding. Researchers are not merely crafting jewelry or decorative items; they are weaving metal with such precision that it begins to feel, drape, and shimmer like one of nature’s most coveted textiles: silk. This is the world of precision metal micro-weaving, an avant-garde discipline where the cold, hard permanence of precious metals is transformed into textiles of breathtaking delicacy and luxury. The implications stretch far beyond aesthetics, hinting at a future where our very definition of fabric is rewritten.

The process itself is a marvel of modern engineering, a stark departure from traditional metalworking. It begins not with a forge and hammer, but with a microscopic loom. Engineers draw precious metals like gold, platinum, and palladium into filaments finer than a human hair, some measuring mere microns in diameter. This requires an extraordinary level of purity and alloy control to ensure the wire is both strong enough to withstand the weaving process and pliable enough to mimic the softness of a silk thread. Any imperfection, any microscopic flaw, would cause the delicate filament to snap under tension, rendering the entire endeavor futile.

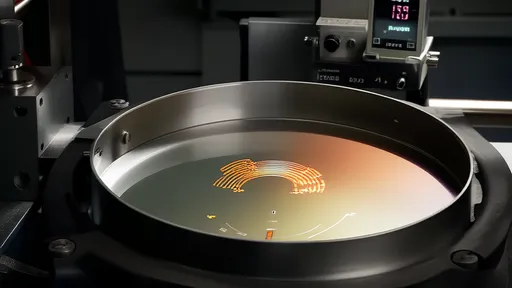

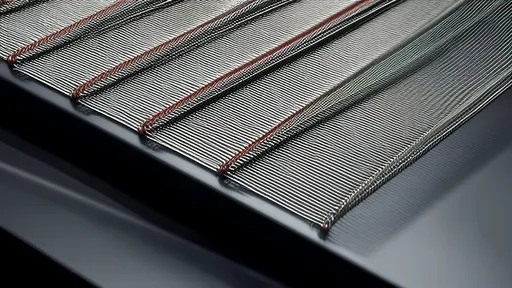

These ultrafine wires are then fed into specialized, computer-controlled looms. These are not the massive, clattering machines of the Industrial Revolution. They are precision instruments, often operating in vibration-dampened, climate-controlled cleanrooms to prevent any external interference. The looms interlace the metallic threads with a meticulousness that borders on the obsessive, replicating the complex weave patterns found in high-grade silk—patterns like twill, satin, and jacquard. The result is a hybrid material: a textile with the structural integrity and conductive properties of metal, but the weight, texture, and fluid movement of silk.

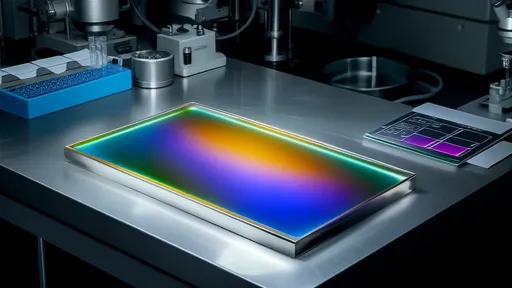

The visual and tactile effect is nothing short of alchemy. The woven metal captures and plays with light in a uniquely captivating way. Unlike solid metal, which reflects light in a uniform glare, or silk, which offers a soft, diffuse sheen, this material does both. The microscopic gaps between the woven threads create a scintillating effect, a dynamic sparkle that shifts and changes as the fabric moves. To the touch, it is cool and smooth at first contact, much like metal, but it yields and flows through the fingers with the surprising softness of a luxury textile. This uncanny valley of materials—familiar yet fundamentally new—is its most disarming and alluring quality.

The potential applications for this technology are as diverse as they are profound. In the realm of high fashion and haute couture, designers are already experimenting with gowns and accessories that blend this metallic fabric with traditional silks and organzas, creating garments that are literally woven with light. A dress that shimmers with its own ethereal glow on the runway, without a single LED in sight, is now a tangible reality. This isn't just clothing; it's wearable sculpture, a statement on the fusion of organic inspiration and technological execution.

Yet the impact promises to extend far beyond the catwalk. The inherent conductivity of the metal threads opens a world of possibilities in wearable technology. Imagine a sports shirt that monitors your vitals through its very fabric, with sensors woven seamlessly into the material instead of being attached as bulky external devices. Or consider smart upholstery in luxury automobiles or aircraft cabins—seats that can heat themselves evenly or integrate lighting and communication systems directly into the textile, all while feeling as luxurious as the finest silk. This material could erase the line between interface and object.

Perhaps one of the most compelling applications lies in conservation and restoration. Museums and preservation societies face a constant battle against time, with historic textiles and tapestries fading and decaying. This metal-weaving technique offers a radical solution: the creation of perfect, permanent metallic replicas of these priceless artifacts. A replica of a centuries-old silk banner, woven in platinum and gold, would never fade, tear, or be devoured by moths. It would allow future generations to experience the visual splendor of history in a durable, stable form, while the original could be retired to a carefully controlled dark storage, its decay halted.

However, this innovation does not arrive without its own set of challenges and philosophical questions. The cost of production is currently astronomical, placing it firmly in the domain of luxury goods and specialized industrial applications for the foreseeable future. Scaling the process to make it accessible remains a significant engineering hurdle. Furthermore, the creation of a "synthetic silk" from non-renewable metal ores invites a dialogue about sustainability and value. Is the permanence of a metal tapestry a virtue for preservation, or does it represent a shift towards a more resource-intensive luxury? The industry will need to grapple with its environmental footprint as the technology matures.

Ultimately, precision metal micro-weaving is more than a technical achievement; it is a new form of artistic and functional expression. It represents a point of convergence where the ancient human impulse to adorn and create meets the limitless potential of micro-engineering. By mimicking the complex beauty of a spider’s web or a silkworm’s cocoon in precious metal, scientists and artists are not just copying nature—they are engaging in a dialogue with it, offering a metallic echo of one of its most elegant creations. This is not the end of silk’s story, but the beginning of an exciting, dazzling new chapter.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025