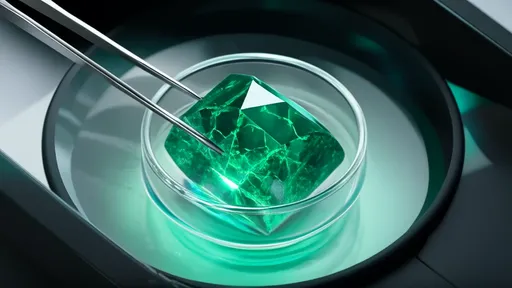

In the intricate world of gemology, the manipulation of minuscule gemstones presents a unique set of challenges that demand both precision and ingenuity. When dealing with specimens as small as 0.5mm, the line between successful handling and potential loss or damage is exceedingly fine. The process of grasping and securing such tiny treasures under a microscope is not merely a procedural step; it is a fundamental aspect of the craft that requires a deep understanding of both the tools and the materials involved.

The primary instrument for this delicate task is the microscope itself, which provides the essential magnification needed to even perceive the gemstone clearly. However, magnification alone is insufficient. The human hand, no matter how steady, is incapable of the micron-level precision required. This is where specialized micromanipulation tools come into play. These are not standard tweezers or picks, but highly engineered devices often equipped with vacuum suction, micro-claws, or adhesive surfaces. The choice of tool is critical and depends heavily on the gem's properties—its hardness, cut, and surface finish. A vacuum pickup tool, for instance, is excellent for smooth, flat surfaces but may struggle with a highly faceted or porous stone where a seal cannot be properly formed.

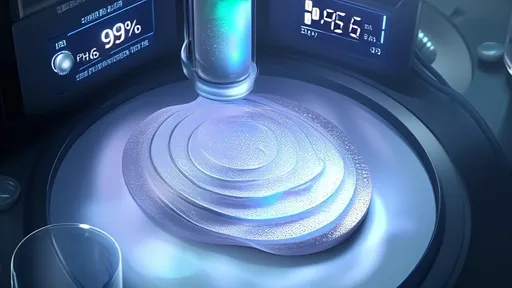

The underlying physics of adhesion and grip at this scale defies everyday intuition. Macroscopic concepts like friction become less reliable, and surface forces such as Van der Waals forces and electrostatic attraction start to dominate. A speck of dust or a static charge, negligible in larger operations, can cause a 0.5mm gem to jump unpredictably or cling stubbornly to a tool. Practitioners often work in controlled environments with anti-static measures and humidity control to mitigate these effects. The goal is to create a predictable interaction between the tool and the gemstone, allowing for a controlled pickup, precise movement, and secure placement.

Once the gem is grasped, the next critical phase is fixation. The gem must be held immobile for examination, measurement, or further processing like setting or repair. This is typically achieved through a stage fixture or a specialized holder. These holders are marvels of micro-engineering, often custom-machined to accommodate specific gem shapes and sizes. They might employ a gentle mechanical clamp, a low-tack adhesive wax, or a vacuum chuck. The paramount concern is security without compromise. The holding force must be strong enough to prevent any movement during manipulation, yet it must be utterly non-destructive, leaving no marks, residues, or stresses on the precious stone.

Mastering this art is a testament to the gemologist's skill and patience. It is a dance of extreme delicacy, performed under the watchful eye of the microscope. Each successful manipulation of a 0.5mm gem is a small victory, a demonstration of human dexterity augmented by technology to interact with beauty on a scale that is almost invisible to the naked eye. This meticulous process ensures that even the smallest gems can be studied, appreciated, and ultimately showcased in all their intricate glory.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025